Warehouse racking could be the central part in effective storage management, letting companies to enhance Place, enhance accessibility, and boost productiveness inside their facilities. With numerous racking techniques out there, warehouses can efficiently organize and keep elements based upon their particular requirements, from little matters to bulk products. Picking the correct racking system not just maximizes storage capability but additionally makes certain employee protection and smooth functions.

Varieties of Warehouse Racking

Quite a few forms of racking programs are Commonly present in warehouses, Each and every with exclusive rewards tailor-made to various storage demands:

Selective Pallet Racking: This will be the most Repeated racking procedure, delivering immediate obtain to each pallet. It’s very adaptable, rendering it perfect for warehouses that has a higher turnover of varied products. Selective racking maximizes accessibility, eventhough it won't be as Room-productive as other programs.

Generate-In/Drive-Via Racking: Designed for high-density storage, travel-in racking lets forklifts to get in the racking system to carry and retrieve pallets. It’s compatible for storing massive portions of similar items in A final-in, initial-out (LIFO) system. Generate-as a result of racking, alternatively, follows a first-in, initially-out (FIFO) system and it truly is exceptional for inventory rotation.

Cantilever Racking: Ideal suited to storing prolonged, bulky goods like pipes, lumber, and metal rods, cantilever racks present open fronts that simplify loading and unloading. They are sometimes found in building and producing services in which lengthy products have to have flexible storage.

Thrust Back Racking: This technique operates within the number of nested carts that roll together rails, enabling pallets to be saved two to six deep. It’s an economical, large-density Option for things that don’t have to have speedy retrieval, functioning over a LIFO technique.

Mezzanine Racking: By including a further or perhaps third stage to some warehouse, mezzanine racking properly doubles or triples available living place without having increasing your constructing alone. This method is perfect for maximizing vertical Place.

Advantages of Helpful Warehouse Racking

An efficient racking method drastically improves warehouse operations by optimizing House utilization, enhancing access, and decreasing retrieval moments. This sales opportunities to higher inventory administration, as objects are very easily obtainable and arranged, which minimizes labor fees and increases productiveness.

Racking techniques also promote basic safety by way of supplying structured and steady storage. Properly made racks sluggish up the hazard of mishaps, making certain a safe surroundings for both of those personnel and stock. Also, perfectly-managed racking systems minimize damage to saved merchandise, boosting inventory lifespan.

Deciding on the Suitable Racking Process

Deciding on the right racking process is dependent upon factors like available Place, inventory sort, turnover rate, and price range. An intensive assessment of storage wants and operational circulation could be handy for choosing a racking technique that supports streamlined workflows and maximizes warehouse performance. Thoroughly executed, warehouse racking is surely an read more expense that pays off in Place savings, security, and extensive-term productivity.

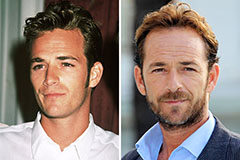

Luke Perry Then & Now!

Luke Perry Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!